Plastic Processing

- Home

- Product

- CNC Precision Machining

- Plastic Processing

- Engineering plastics

Contact us

Swipe right⭢

Introduction to 8 common plastic processing methods, engineering plastic molding processing technology and applications

Plastic molding processing classification

Thermosetting plastic molding

Thermosetting plastic molding processing methods include compression molding, transfer molding and casting molding. Compression molding is the process of placing heated plastic powder or granules into a mold and applying pressure to shape it. Transfer molding is to put the plastic material into a cylinder, transfer it to the mold through a piston, and then apply pressure to solidify it. Casting is the process of injecting heated plastic liquid into a mold and solidifying it into shape.

Thermoplastic Plastic Molding

Thermoplastic plastic molding processing methods mainly include injection molding, extrusion molding and blow molding. Injection molding is the process of injecting heated plastic into a mold and taking out the finished product after cooling. Extrusion molding is the process of heating plastic materials and squeezing them into continuous shapes, such as pipes, plates, etc. Blow molding is the process of blowing heated plastic into a hollow shape, and is commonly used to make bottles, containers, etc.

8 common plastic processing methods and applications

There are various methods for plastic molding processing. The following are some common methods:

1️⃣ Injection Molding

Injection molding is one of the most widely used plastic processing methods. The heated and molten plastic is injected into the mold under high pressure, and the finished product is taken out after it cools and solidifies. Suitable for precision parts and mass production.

EX: 3C product housings, automotive panels, medical equipment housings, bicycle accessories

2️⃣ Extrusion Molding

An extruder is used to extrude heated plastic material into a continuous shape such as a tube, rod or film. This method is suitable for producing long strips or sheets of products and can be processed later.

EX: high-precision PTFE tubes, wire sheaths, sealing strips, industrial conveying pipes

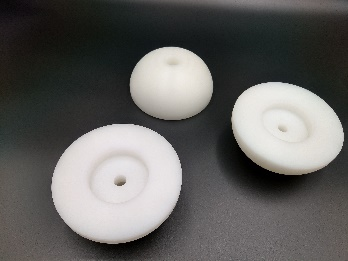

3️⃣ Compression Molding

Put the plastic raw material into the mold, heat it and apply pressure to shape it. It is suitable for thicker or more complex parts, especially for products that require high temperature resistance and high strength.

EX: Industrial sealing gaskets, automotive anti-vibration parts, high-strength insulation parts

4️⃣ Blow Molding

Blowing technology is used to expand plastic materials into the shape of the mold to create hollow structure products suitable for liquid or gas storage containers.

EX: fuel tanks, chemical storage barrels, industrial water bottles, sports water bottles

5️⃣ Blown Film Extrusion

The melted plastic is extruded through a film blowing machine to produce a film-like material, which is widely used in applications such as packaging and protective film.

EX: Food grade vacuum packaging film, industrial moisture-proof film, medical sterilization bag

6️⃣ Transfer Molding

The plastic material is first heated to a fluid state, then injected into the mold under high pressure, and then cooled and formed after filling. It is suitable for parts with complex details and high precision requirements.

EX: precision electronic connectors, sealing gaskets, special-shaped mechanical parts

7️⃣ Casting Molding

Pour liquid plastic into the mold and solidify it through natural cooling or chemical reaction. It is suitable for transparent or highly light-transmitting products and applications that require extremely low stress deformation.

EX: Acrylic window, optical grade lens, precision measuring instrument cover

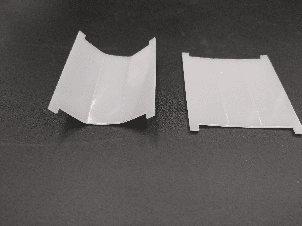

8️⃣ Thermoforming

After heating the plastic sheet to a plastic state, it is formed into the shape of the mold through vacuum or pressure. It is suitable for large-sized, thin-walled plastic products.

EX: industrial protective covers, medical equipment pallets, logistics turnover boxes, automotive interior panels

Introduction to Teflon Engineering Plastic Processing Materials | Features and Applications

PE|聚乙烯(Polyethylene)

|

PP|聚丙烯(Polypropylene)

|

UPE|超高分子量聚乙烯(UHMW-PE)

|

PEEK|聚醚醚酮(Polyether Ether Ketone)

|

HDPE|高密度聚乙烯(High-density Polyethylene)

|

PVC|聚氯乙烯(Polyvinyl Chloride)

|

ABS|丙烯腈丁二烯苯乙烯(Acrylonitrile Butadiene Styrene)

|

POM|聚甲醛(Polyoxymethylene)

|

PA|尼龍(Polyamide, PA6 / PA66)

|

MC尼龍|混合型尼龍(Mixed Composition Nylon)

|

And other engineering plastic materials, such as: PPS (polyphenylene sulfide), PMMA (acrylic), PTFE (polytetrafluoroethylene), ETFE, PVDF, PC (polycarbonate), or other available materials.

Once the drawings, dimensions, tolerances, and production quantities are confirmed, we can provide a quote.

Our company is equipped with various precision CNC processing machines and provides various Teflon finishing products. Processing includes precision CNC lathes, milling machines, punching machines, molding, injection molding, welding, spraying, cutting, etc. All engineering plastic products can be customized, welcome to inquire.

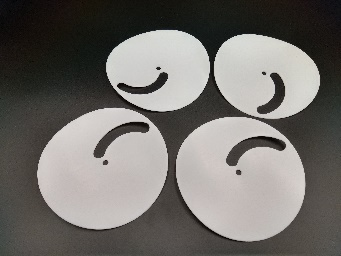

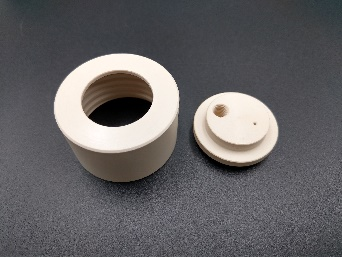

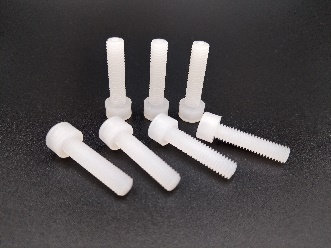

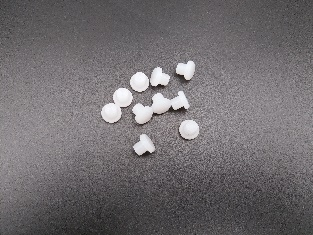

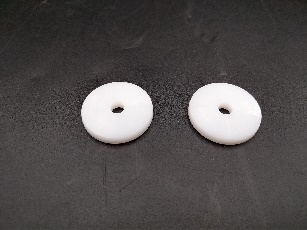

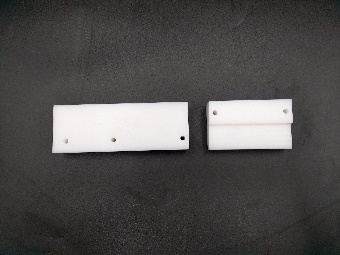

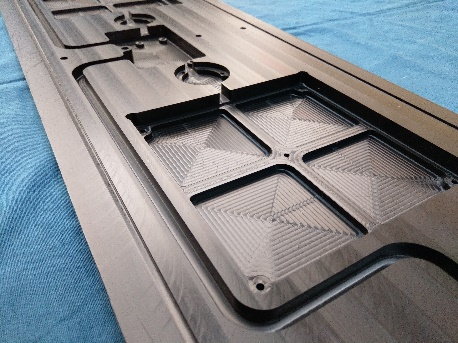

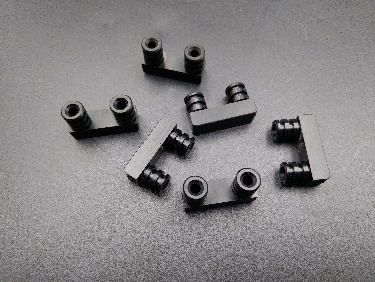

Plastic Processing Products - POM Actual Case:

Plastic Processing Products - PEEK Actual Case:

Plastic Processing Products - PP Actual Case:

Plastic Processing Products - PE Actual Cases:

Plastic Processing Products - UPE Actual Cases:

Plastic Processing Products - HDPE Actual Case:

Plastic Processing Products - PPS Actual Cases:

Complete plastic processing process

- Personal consultation – Contact us by phone or email, and our professional team will help you quickly understand your product needs.

- Requirements confirmation – Confirm details of drawing design (2D/3D), sample specifications, tolerance requirements, and order quantity.

- Prototype production – Produce preliminary samples based on the design, conduct testing and functional verification, and adjust the design as needed.

- Quality Inspection – Precision quality inspection is performed through ruler measurement and projection testing equipment to ensure that products meet standards.

- Mass production delivery – Provide customized packaging and pallet shipment according to customer needs to ensure the safe delivery of products to the designated location.

Why choose us?

- ✅ One-stop service: from design, proofing to mass production, full control, reducing communication costs

- ✅ Precision manufacturing: using CNC, grinding machines, lathes and other high-end equipment to ensure processing accuracy

- ✅ Strict quality control: full quality inspection to achieve zero-defect production standards

- ✅ Fast delivery: optimize production process, shorten delivery time and improve market competitiveness

Related products

TEL: 02-8522-1177

TEL: 02-8522-1177 FAX: 02-8522-1178

FAX: 02-8522-1178 MAIL: ptfe@liako.com.tw

MAIL: ptfe@liako.com.tw ADD:No. 12, Lane 660, Huacheng Road, Xinzhuang District, New Taipei City 24253

ADD:No. 12, Lane 660, Huacheng Road, Xinzhuang District, New Taipei City 24253