【Teflon spraying, gaskets and braided tubes】Professional metal processing and laboratory Teflon products - LIAKO TECHNOLOGY CORP Co., Ltd.

ONE STOP REACHING

One-stop service

Our professional services

Design, proofing, manufacturing, mass production, technical support, one-stop service

01

01develop

Development

02

02design

Design

03

03Proofing

Proofing

04

04verify

Verify

05

05production

Production

06

06Adjustment

Adjustment

07

07production

Production

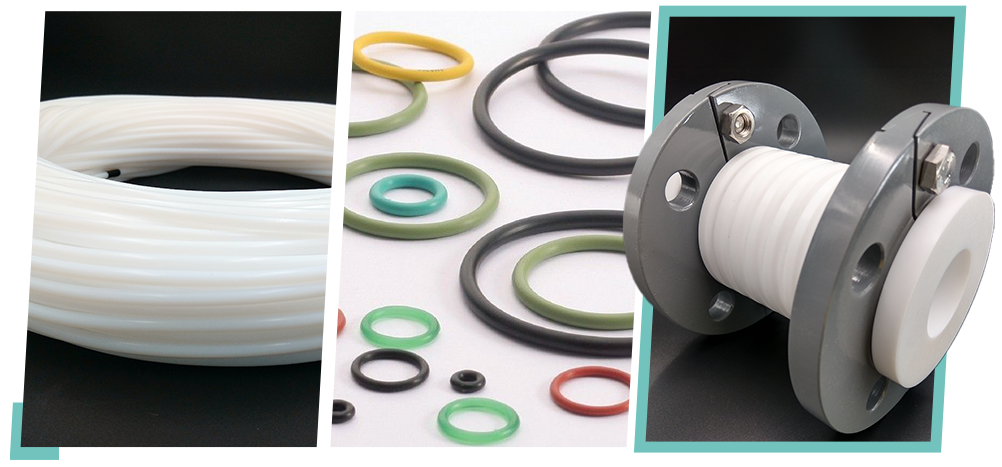

Product

ABOUT US

Integrity, quality, service, innovation

Top Teflon Expert

Provide professional customized design and manufacturing services

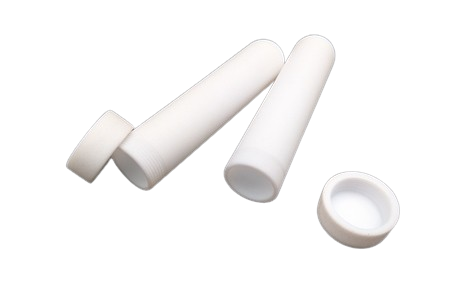

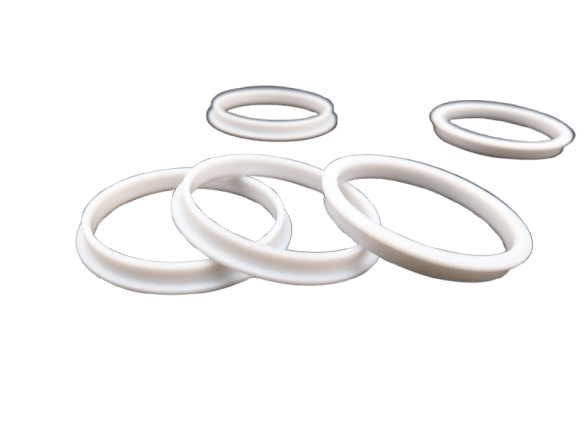

LIAKO TEFLON MASTER ( LIAKO TECHNOLOGY CORP Co., Ltd.) is committed to the design and manufacture of Teflon products. We can provide both public specification products and customized designs for pipe fittings, engineering plastic CNC automated processing (lathe, milling machine, stamping, molding, injection molding, injection, mold opening), Teflon spraying/welding, etc. It adopts German advanced equipment technology and various high-end material processes, and is highly recognized by domestic and foreign companies.

Latest news

-

Latest Teflon Industry

Latest Teflon IndustryCOMPUTEX 2025 Meet you

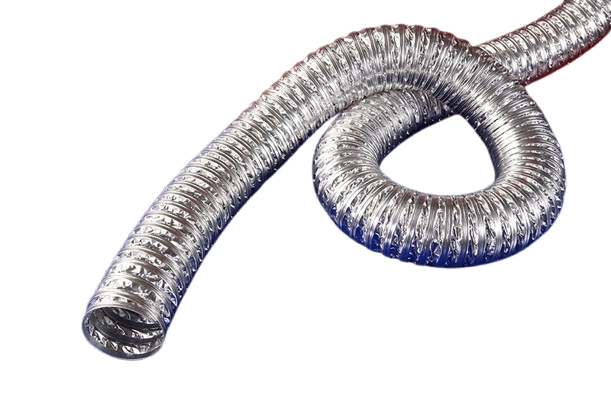

We have prepared water cooling pipe solutions for servers, e-sports, energy storage, and electric vehicles. We not only showcase our products, but also want to share with you the stories and persistence behind them.

-

Teflon knowledge

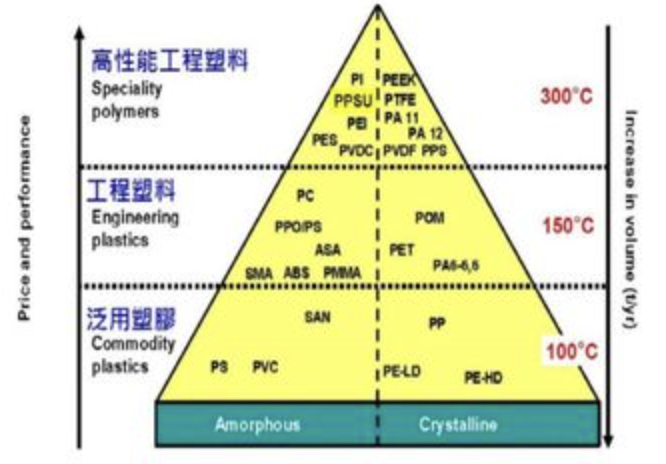

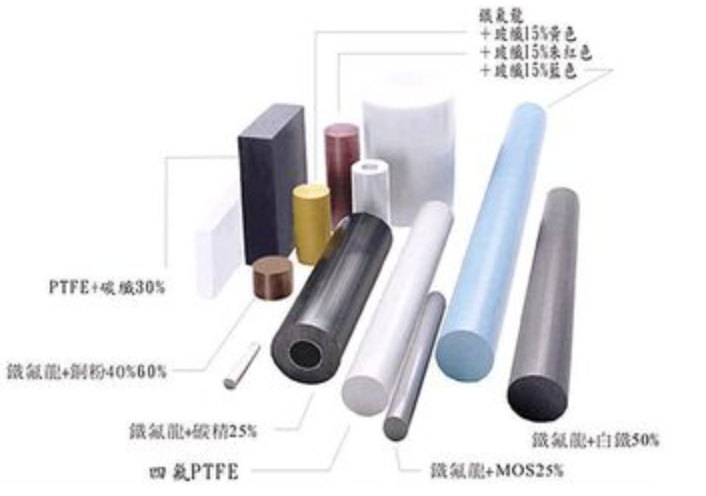

Teflon knowledgeCharacteristics of Common Engineering Plastic Materials

-

Teflon knowledge

Teflon knowledgeTeflon composite material properties

-

Teflon knowledge

Teflon knowledgeBasic types of Teflon

Corrosion resistance: Able to withstand corrosion from various chemicals, including acids, alkalis, solvents, etc., and suitable for chemical pipelines and equipment.

-

Teflon knowledge

Teflon knowledgeWhat is Teflon?

Teflon (scientific name: polytetrafluoroethylene, English name: Polytetrafluoroethene, abbreviated as PTFE) is a widely used fluorocarbon polymer. It was originally developed for defense and high-tech uses, but has since spread to civilian use. Teflon is known as the "King of Plastics" for its outstanding properties. Teflon is not only not wetted by water and oil, but also has excellent resistance to acids, alkalis and various organic solvents. Therefore, it is often used as a coating material for non-stick pans and as a container for storing and transporting corrosive chemical

-

Latest Teflon Industry

Latest Teflon IndustryApplication and technological development of Teflon coatings – Differences and developments between food grade and industrial gr

In recent years, Teflon coatings have shown excellent performance and wide application in food-grade and industrial-grade applications. Food-grade coatings are safe, reliable and have strong anti-adhesive properties, and are mainly used in food processing; while industrial-grade coatings are widely used in high temperature, high pressure and corrosive environments due to their durability and high efficiency. With the advancement of technology and materials, Teflon coatings will continue to improve in the future to meet the increasingly diverse needs of the global market and promote industrial

-

Latest Teflon Industry

Latest Teflon IndustryLatest technology | Application and development of Teflon welding and electric heaters

In recent years, the importance of Teflon materials in the fields of welding technology and electric heaters has continued to emerge. Teflon welding technology is widely used in the manufacturing industry. It has advantages such as high temperature resistance and strong chemical stability, and shows potential especially in the aerospace and automotive industries. As an emerging heating technology, Teflon electric heaters face high costs and technical challenges, but their rapid heating and long life characteristics are suitable for various needs. As the global demand for environmental protecti

-

Latest Teflon Industry

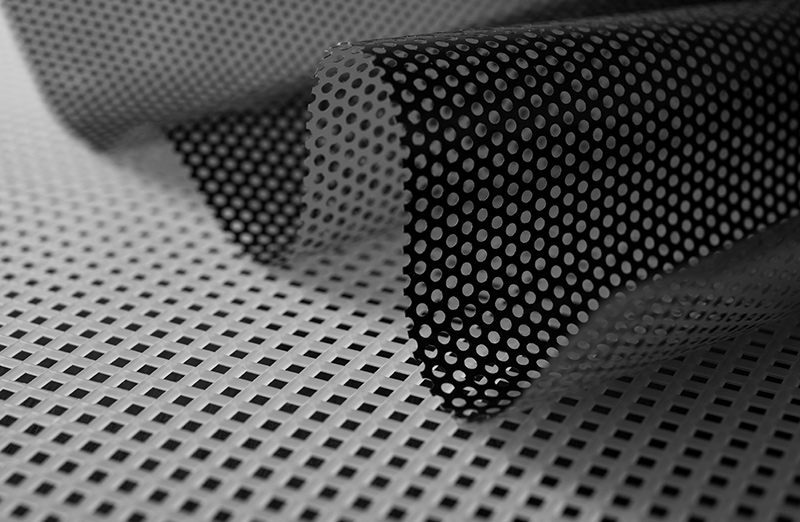

Latest Teflon IndustryLatest technology|Innovation in the manufacturing process of Teflon fiberglass cloth and PTFE Teflon tube

Teflon materials play an important role in modern industry due to their unique physical and chemical properties. This article takes an in-depth look at the latest process technologies for Teflon fiberglass cloth and PTFE Teflon tubing, as well as their wide range of industrial applications. Teflon glass fiber cloth exhibits high temperature resistance, corrosion resistance and wear resistance through special weaving and hot pressing processes, and is widely used in chemical, aerospace and medical fields. PTFE Teflon tube plays an important role in the chemical, electronics and other industries